Creating Shared Value (CSV) by Daiken Businesses

The Daiken Group delivers value to society by operating businesses that utilize our unique industrial materials and technologies to respond to a variety of social issues and needs.

Initiatives for materiality “Realization of a resource-recycling and recycle-oriented society”

Initiatives for materiality “Realization of a resource-recycling and recycle-oriented society”

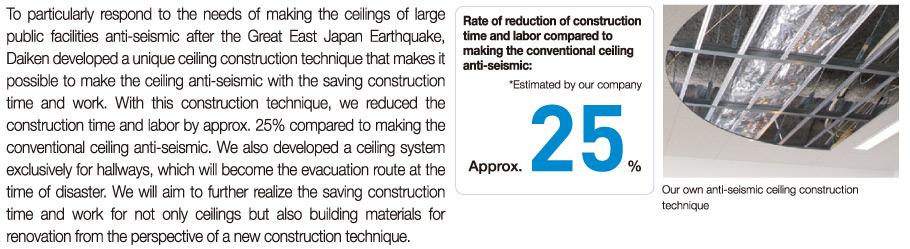

Contribution to carbon neutrality by utilizing wood resources

By pursuing the use of wood resources for materials, turn the living space into “The second forest”

Social issues and needs

While the countermeasures for climate change have become a pressing global issue, the importance of protecting and growing forests that have the functions to absorb CO2 and store it as carbon to reduce greenhouse gas emissions and using wood resources as materials, in addition to energy saving and shifting to renewable energy, has been increasing.

Daiken's strengths and value creation

Initiatives for materiality “Realization of a resource-recycling and recycle-oriented society”

Initiatives for materiality “Realization of a resource-recycling and recycle-oriented society”

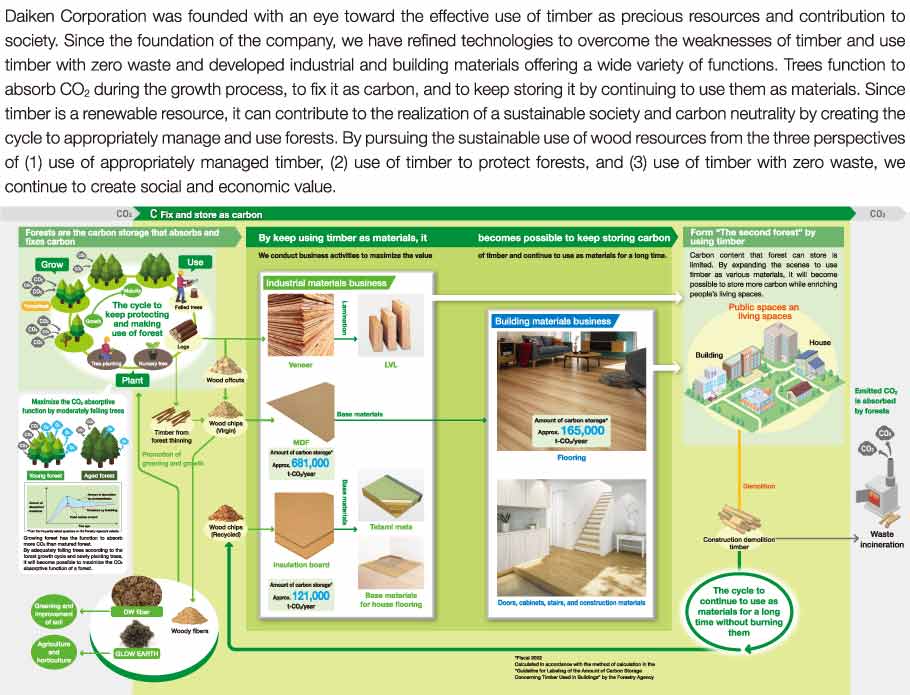

Promotion of the use of domestic timber

Promote the use of domestic timber with special MDF that offers excellent water resistance

Social issues and needs

Japan is one of the world's most forested countries with about two-thirds of the land covered in forest. Therefore, domestic timber should be more actively used in order to foster healthy forests that fulfill various needs, such as absorbing CO2 and prevention of landslides. The Japanese government is aiming to increase wood self-sufficiency to 50% by 2025.

Daiken's strengths and value creation 1

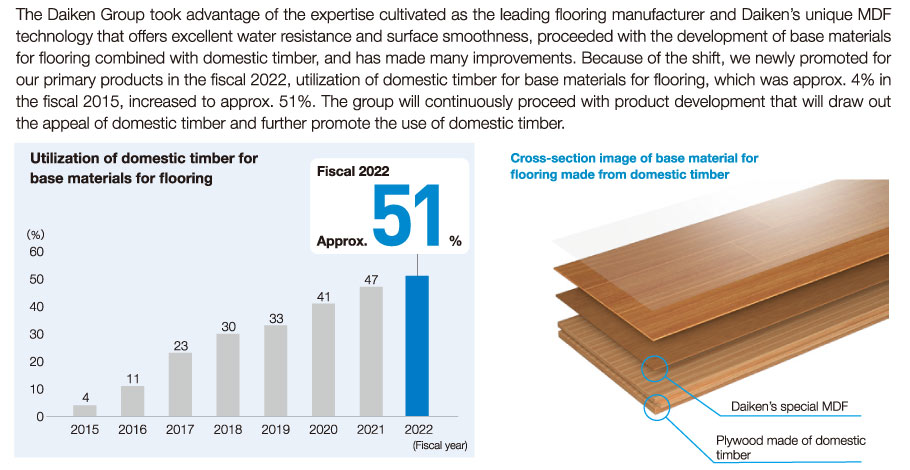

Expanding the scenes to utilize domestic timbers with the wood hardening technology

Daiken's strengths and value creation 2

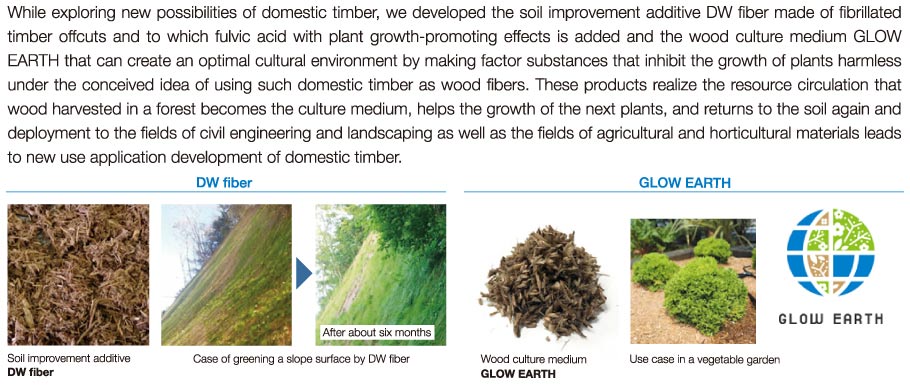

New use application development of wood materials

Daiken's strengths and value creation 3

Initiatives for materiality “Realization of a resource-recycling and recycle-oriented society”

Initiatives for materiality “Realization of a resource-recycling and recycle-oriented society”

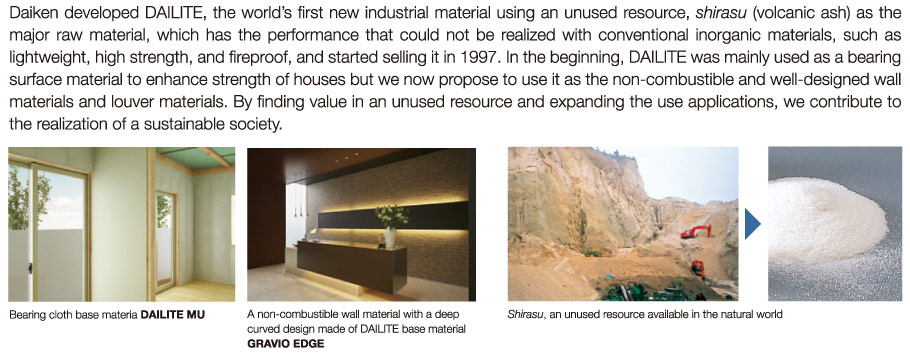

Effective utilization of unused resources

Expansion of the utilization of unused resources using non-combustible materials that offer excellent durability

Social issues and needs

While everyday lives becoming more convenient and affluent, limited resources and energy on earth have been heavily consumed and there have been growing concerns about the depletion of natural resources. To respond to these issues, pursuit of sustainable production and consumption, such as effective utilization of renewable resources and unused resources and the reduction of waste, has become crucial.

Daiken's strengths and value creation

Initiatives for the fulfillment of materiality, “User needs in the new normal era”

Initiatives for the fulfillment of materiality, “User needs in the new normal era”

Creating a safe, secure, healthy, and comfortable space

Creating a safe space to live together with the elderly

Social issues and needs

Japanese society is more rapidly aging than other developed countries and becoming a super-aging society with one in four people aged 65 or over. Amid concerns about social problems with elderly people providing care for elderly people, living spaces where people can live with peace of mind even when they get older are required.

Daiken's strengths and value creation 1

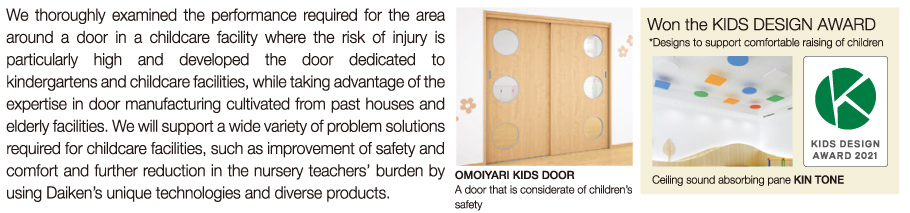

Creating spaces where children can spend the time safely

Social issues and needs

With the increase in women's participation in society and in childcare facilities that increasingly grow in importance, it is imperative to create safer facilities and reduce nursery teachers' burden in addition to the problem of children on the waiting list due to the lack of facilities.

Daiken's strengths and value creation 2

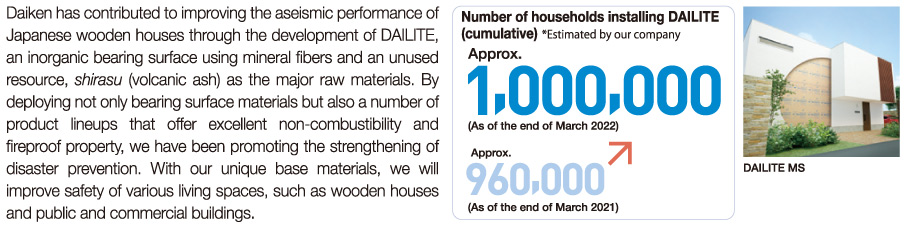

Seismic resistance / Strengthening of disaster prevention

Social issues and needs

Japan has been devastated by earthquakes many times, including the Great East Japan Earthquake. Large earthquakes, such as the Nankai trough earthquake, are predicted with high probability to occur in the future, and the Japanese government has set a target for seismic resistance ratios and promotes the seismic resistance and the strengthening of disaster prevention for houses and buildings.

Daiken's strengths and value creation 3

Expansion of the antiviral products

Social issues and needs

With the pandemic outbreak of infectious disease, awareness of health and clean environments has been rapidly increasing and the needs for sanitary measures for and safety of living spaces and public spaces where people gather have been expanding.

Daiken's strengths and value creation 4

Improvement of the sound environment in living spaces

Social issues and needs

With the changes of the times, issues concerning sound in daily lives have become diversified. Particularly in the COVID-19 crisis, the needs for the prevention of sound leakage and reverberation have been rapidly increasing because of the increase in working at home and online meetings.

Daiken's strengths and value creation 5

Initiatives for the fulfillment of materiality, “User needs in the new normal era”

Initiatives for the fulfillment of materiality, “User needs in the new normal era”

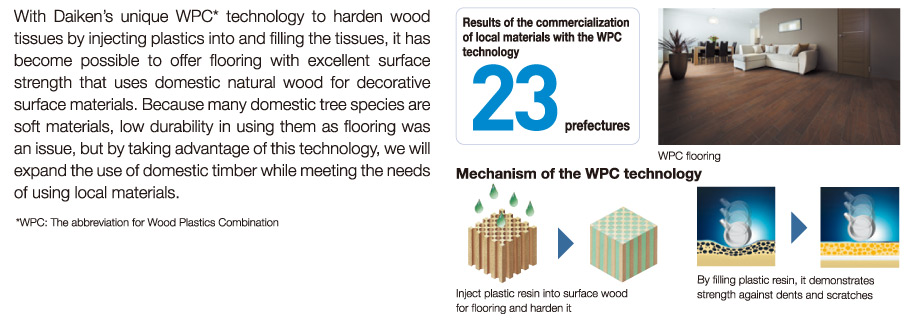

Development of labor saving type products and techniques

Contributing to the anti-seismic ceiling by developing the labor-saving construction technique

Social issues and needs

A shortage of workers has become an aggravated problem in the construction industry. On the other hand, while the Building Standards Act revised after the Great East Japan Earthquake requires higher aseismic performance of the ceilings of large public buildings, there was an issue that it requires much time and labor in making existing ceiling anti-seismic.

Daiken's strengths and value creation